1802

History

>15

>10

k

k

k

>10

The history of the Alexandrovsk Machine Building Plant began in 1802. This became possible thanks to decree No. 1455 of the UralCollegium of Mining, according to which Count V. A. Vsevolozhsky was allowed to build an ironworks on the Lytva River.

Total length of produced conveyors

Mining equipment issued

Total alloy casting products produced

Date of foundation

units

km

tons

JSC AMZ has a full production cycle of equipment.

We get raw materials and components. We issue ready-made equipment.

We get raw materials and components. We issue ready-made equipment.

Turning of large parts

Tooth cutting equipment

Longitudinal planing

of billets

of billets

Smelting of grade steel, cast iron and casting

into molds

into molds

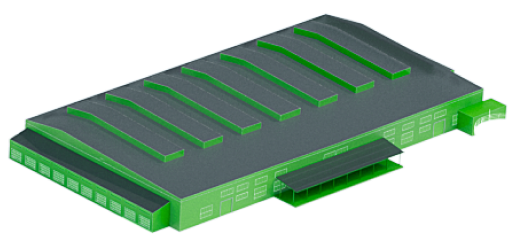

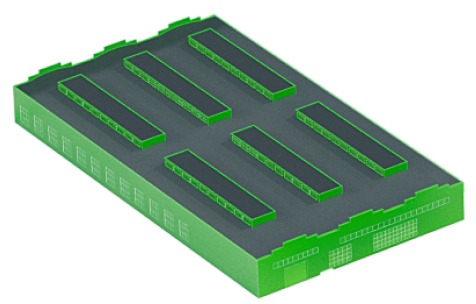

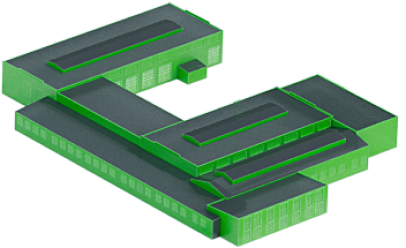

INDUSTRIAL CAPACITY

Land plot 90 Ha

78 000 m² production premises

7 production and

3 auxiliary workshops

3 auxiliary workshops

Own design bureau

Up to 5 m in length, 2 m in diameter and up to 30 tons of

weight

weight

Diameter up to 3 m, up to 10 tons of weight

Up to3.2x8.0 m, weight up to 100 tons

From 2 to 2000 kg

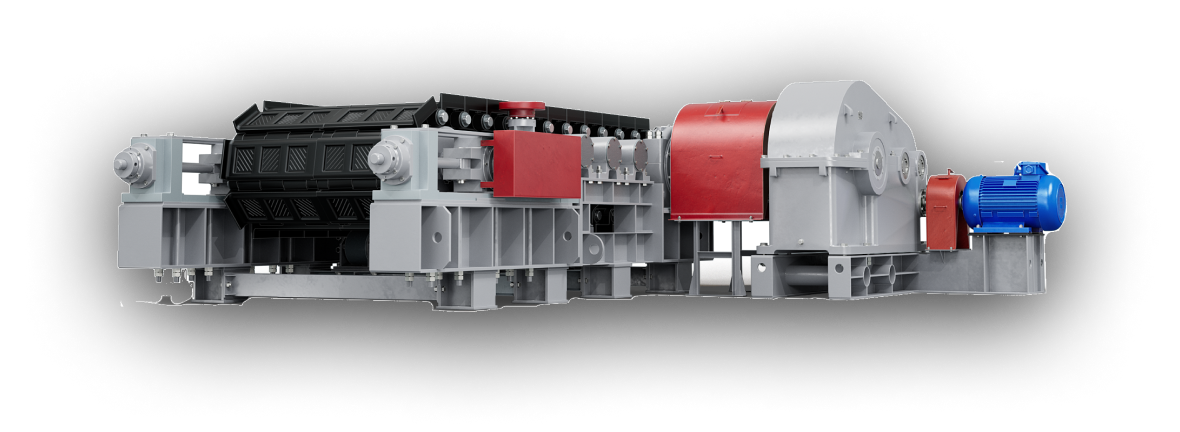

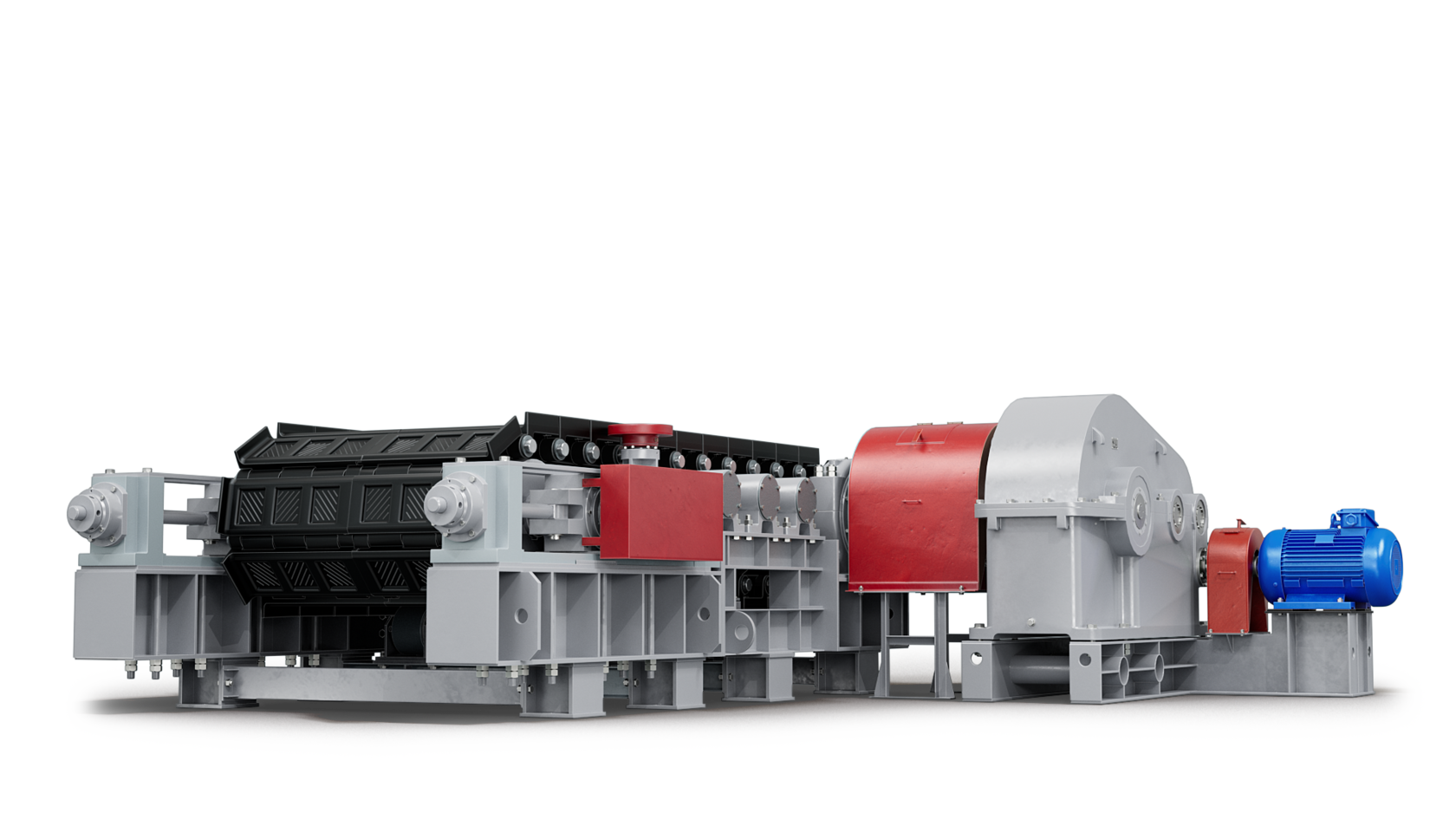

Mechanical Assembly Shop No. 7

Machining, painting and assembly of main conveyors with a width of 1200 mm and more, electric locomotives, plate feeders, trolleys are carried out in the workshop

Machining, painting and assembly of main conveyors with a width of 1200 mm and more, electric locomotives, plate feeders, trolleys are carried out in the workshop

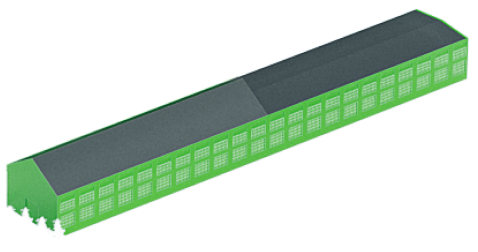

Shop for manufacture and assembly

of rollers No. 20

The workshop manufactures parts and assembly of conveyor rollers: diameter from 89 to 159 mm, length from 200 to 2000 mm

of rollers No. 20

The workshop manufactures parts and assembly of conveyor rollers: diameter from 89 to 159 mm, length from 200 to 2000 mm

Foundry No. 10

In the foundry, castings weighing up to 2000 kg are made by casting in sand-clay molds, from 30L,45L,60L, 35KhML, 65GL

and cast iron SCh10-SCh20

In the foundry, castings weighing up to 2000 kg are made by casting in sand-clay molds, from 30L,45L,60L, 35KhML, 65GL

and cast iron SCh10-SCh20

Forging and press production workshop No. 8

Forging weighing up to 700 kg, forging weighing up to 15 kg are produced in the forging and press workshop, the following types of maintenance are performed: quenching for water and oil, tempering, normalization, cementing, HFC

Forging weighing up to 700 kg, forging weighing up to 15 kg are produced in the forging and press workshop, the following types of maintenance are performed: quenching for water and oil, tempering, normalization, cementing, HFC

Cutting section of workshop No. 3

Cutting of conformations on press scissors: angles from 32х32х4 to 100х100х12, beam channel No. 8U to 30U, pipe.

Cutting of conformations on press scissors: angles from 32х32х4 to 100х100х12, beam channel No. 8U to 30U, pipe.

Mechanical Assembly Shop No. 1

The workshop performs mechanical processing (turning, milling, gear-making),

the manufacture of drums and reducers: cylindrical, conical-cylindrical, screw type.

The workshop performs mechanical processing (turning, milling, gear-making),

the manufacture of drums and reducers: cylindrical, conical-cylindrical, screw type.

Blank production shop, steel structure

assembly and welding shop No. 6

Plasma and gas cutting of rolled sheets, profile punching on various presses, bending, rolling of shells, manual electric arc

and semi-automatic welding

assembly and welding shop No. 6

Plasma and gas cutting of rolled sheets, profile punching on various presses, bending, rolling of shells, manual electric arc

and semi-automatic welding

Mechanical Assembly Shop No. 5

Machining (turning, drilling, milling, planing), painting and assembly of local conveyors up to 1000 mm wide is performed

in the workshop

Machining (turning, drilling, milling, planing), painting and assembly of local conveyors up to 1000 mm wide is performed

in the workshop

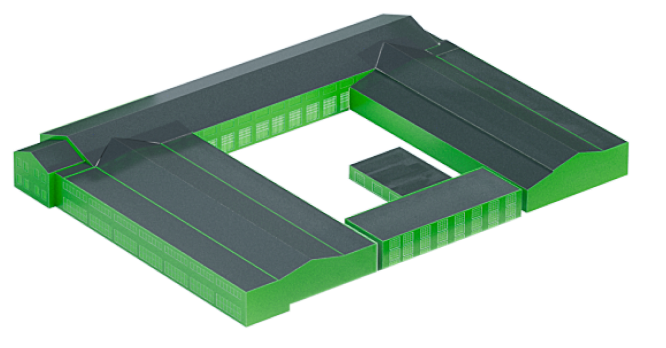

Engineering Building

Currently, JSC AMZ has all the necessary conditions

for the manufacture of high-quality mining equipment

for the manufacture of high-quality mining equipment

Products

The products of JSC AMZ were repeatedly awarded diplomas of the exhibition "Coal and Mining of Russia" and a number

of international awards, and our products are not inferior

in their characteristics to foreign counterparts.

of international awards, and our products are not inferior

in their characteristics to foreign counterparts.

Geography

of Supplies

of Supplies

Apatites

Mining and chemical raw materials

Mining and chemical raw materials

Cherepovets

Black and alloying metal, non-ferrous metal

Black and alloying metal, non-ferrous metal

Vorkuta

Crude minerals

Crude minerals

Berezniki

Mining and chemical raw materials

Mining and chemical raw materials

Gubkin

Nonmetallic feed

Nonmetallic feed

Berezovsky

Non-ferrous metal

Non-ferrous metal

Sol-Iletsk

Mining and chemical raw materials

Mining and chemical raw materials

Anadir

Mineral raw material

Mineral raw material

Norilsk

Non-ferrous metal

Non-ferrous metal

Новокузнецк

Минеральное сырье

Черный и легирующий металл

Минеральное сырье

Черный и легирующий металл

Mirniy

Precious raw materials

Precious raw materials

Neryungri

Crude minerals

Crude minerals

Primorsky Krai, urban-type settlement Vostok

Black and alloying metal

Black and alloying metal

Abaza

Nonmetallic feed

Nonmetallic feed

Vershino-Darasunsky village

Precious raw materials

Precious raw materials

Aktobe, Republic of Kazakhstan

Black and alloying metal

Black and alloying metal

Macedonska Kamenica, Republic of Macedonia

Non-ferrous metal

Non-ferrous metal

Temirtau, Republic of Kazakhstan

Black and alloying metal

Black and alloying metal

Navoi, Republic of Uzbekistan

Non-ferrous metal

Non-ferrous metal

Beshbulak village, Dekhkanabad district, Republic of Uzbekistan

Mining and chemical raw materials

Mining and chemical raw materials